- info@matltech.com

- E2-1-1011 Global Center, No.1700 Tianfu Avenue North, Chengdu 610041, China.

- High Purity Elements & Compounds

- I-Silicon & Compound Semiconductors

- Chem-Metals & Rare Earth Materials

- Izinsimbi Ezincane Nezinhlanganisela Ezithuthukile

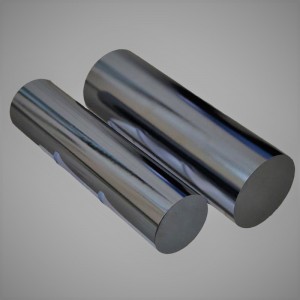

I-Single Crystal Silicon Ingot

Incazelo

I-Single Crystal Silicon Ingotis ngokuvamile ekhulile njenge-cylindrical ingot enkulu ngobuchwepheshe be-doping obunembile kanye nokudonsa i-Czochralski CZ, inkambu yeMagnetic eyenzelwe i-Czochralski MCZ nezindlela ze-Floating Zone FZ.Indlela ye-CZ isetshenziswa kakhulu ekukhuleni kwekristalu ye-silicon yama-ingots amakhulu angama-cylindrical ububanzi obufika ku-300mm esetshenziswa embonini ye-electronics ukwenza amadivaysi e-semiconductor.Indlela ye-MCZ iwukuhluka kwendlela ye-CZ lapho inkambu kazibuthe edalwe yizibuthe kagesi, engakwazi ukuzuza ukuhlushwa komoyampilo ophansi ngokuqhathaniswa, ukugxilisa ukungcola okuphansi, ukugudluka okuphansi kanye nokwehluka kokumelana neyunifomu.Indlela ye-FZ isiza ukufezwa kokuphikiswa okuphezulu okungaphezulu kuka-1000 Ω-cm kanye nekristalu ehlanzekile enokuqukethwe komoyampilo ophansi.

Ukulethwa

I-Single Crystal Silicon Ingot CZ, MCZ, FZ noma FZ NTD enohlobo lwe-n noma i-p-type conductivity e-Western Minmetals (SC) Corporation ingalethwa ngosayizi ongu-50mm, 75mm, 100mm, 125mm, 150mm no-200mm ububanzi (2, 3) .

.

Imininingwane

Omaka

Ukucaciswa Kwezobuchwepheshe

I-Crystal Silicon Ingot eyodwa CZ, MCZ, FZ noma FZ NTDenohlobo lwe-n noma i-p-type conductivity e-Western Minmetals (SC) Corporation ingalethwa ngosayizi ongu-50mm, 75mm, 100mm, 125mm, 150mm kanye no-200mm ububanzi (2, 3, 4, 6 kanye no-8 intshi), ukumaketha <100 >, <110>, <111> enendawo esekelwe kuphakethe lesikhwama sepulasitiki ngaphakathi nebhokisi lebhokisi ngaphandle, noma njengokucaciswa okwenziwe ngendlela oyifisayo ukuze kufinyelelwe esixazululweni esifanele.

| Cha. | Izinto | Ukucaciswa Okujwayelekile | |

| 1 | Usayizi | 2", 3", 4", 5", 6", 8", 9.5", 10", 12" | |

| 2 | Ububanzi mm | 50.8-241.3, noma njengoba kudingeka | |

| 3 | Indlela Yokukhula | CZ, MCZ, FZ, FZ-NTD | |

| 4 | Uhlobo lwe-Conductivity | Uhlobo lwe-P / i-Boron doped, uhlobo lwe-N / Phosphide edotshiwe noma e-Un-doped | |

| 5 | Ubude mm | ≥180 noma njengoba kudingeka | |

| 6 | Ukuqondisa | <100>, <110>, <111> | |

| 7 | Ukungazweli Ω-cm | Njengoba kudingeka | |

| 8 | Okuqukethwe kwekhabhoni a/cm3 | ≤5E16 noma njengoba kudingeka | |

| 9 | Okuqukethwe komoyampilo a/cm3 | ≤1E18 noma njengoba kudingeka | |

| 10 | Ukungcoliswa kwensimbi a/cm3 | <5E10 (Cu, Cr, Fe, Ni) noma <3E10 (Al, Ca, Na, K, Zn) | |

| 11 | Ukupakisha | Isikhwama sepulasitiki ngaphakathi, ikesi leplywood noma ibhokisi lebhokisi ngaphandle. | |

| Uphawu | Si |

| Inombolo Ye-athomu | 14 |

| Isisindo se-Atomic | 28.09 |

| Isigaba Sezinto | I-Metalloid |

| Iqembu, Isikhathi, Vimba | 14, 3, p |

| Isakhiwo sekristalu | Idayimane |

| Umbala | Okumpunga okumnyama |

| I-Melting Point | 1414°C, 1687.15 K |

| Iphuzu elibilayo | 3265°C, 3538.15 K |

| Ukuminyana ku-300K | 2.329 g/cm3 |

| Ukumelana kwangaphakathi | 3.2E5 Ω-cm |

| Inombolo ye-CAS | 7440-21-3 |

| Inombolo ye-EC | 231-130-8 |

I-Single Crystal Silicon Ingot, lapho isikhule ngokuphelele futhi ifaneleka ukumelana kwayo, okuqukethwe ukungcola, ukuphelela kwekristalu, usayizi nesisindo, igxiliswa kusetshenziswa amasondo edayimane ukuze ayenze ibe isilinda esiphelele ukuya kububanzi obufanele, bese ingena inqubo yokubhala ukuze isuse amaphutha emishini ashiywe inqubo yokugaya. .Ngemva kwalokho i-cylindrical ingot isikwa ibe amabhulokhi anobude obuthile, futhi inikezwa inotshi kanye nesicaba esiyisisekelo noma sesibili ngamasistimu okubamba amawafa azenzakalelayo ukuze aqondaniswe ukuze ahlonze umumo we-crystallographic kanye nokusebenza ngaphambi kwenqubo yokusika i-wafer engezansi komfula.

Amathiphu Okuthenga

- Isampula Itholakala Lapho Ucelwa

- Ukuphepha Ukulethwa Kwempahla Nge-Courier/Air/Sea

- Ukuphathwa Kwekhwalithi ye-COA/COC

- Ukupakisha Okuvikelekile & Kalula

- Ukupakisha Okujwayelekile kwe-UN Kuyatholakala Lapho Ucelwa

- ISO9001:2015 Certified

- Imigomo ye-CPT/CIP/FOB/CFR Nge-Incoterms 2010

- Imigomo Yokukhokha Eguquguqukayo T/TD/PL/C Iyamukeleka

- Amasevisi Aphelele Asemuva Kokuthengisa

- Ukuhlolwa Kwekhwalithi Ngesikhungo Sesikhathi Esigcwele

- Ukuvunyelwa Kwemithethonqubo ye-Rohs/REACH

- Izivumelwano Ezingadaluli NDA

- Inqubomgomo Yezambiwayo Engangqubuzani

- Ukubuyekezwa Okujwayelekile Kokuphathwa Kwemvelo

- Ukufezekiswa Kwesibopho Somphakathi

I-Single Crystal Silicon Ingot

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu