- info@matltech.com

- E2-1-1011 Global Center, No.1700 Tianfu Avenue North, Chengdu 610041, China.

- High Purity Elements & Compounds

- I-Silicon & Compound Semiconductors

- Chem-Metals & Rare Earth Materials

- Izinsimbi Ezincane Nezinhlanganisela Ezithuthukile

I-Silicon Carbide SiC

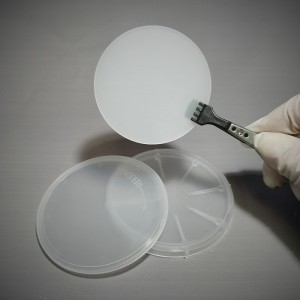

Incazelo

I-Silicon Carbide Wafer SiC, ilukhuni ngokwedlulele, inhlanganisela yekristalline ekhiqizwe ngokwenziwa ye-silicon nekhabhoni ngendlela ye-MOCVD, futhi imibukisoigebe layo elihlukile lebhendi elibanzi kanye nezinye izici ezithandekayo ze-coefficient ephansi yokwanda okushisayo, izinga lokushisa eliphakeme lokusebenza, ukukhishwa okuhle kokushisa, ukulahleka kokushintshashintsha okuphansi kanye nokulahlekelwa kwe-conduction, ukonga kakhudlwana kwamandla, ukuqhutshwa kokushisa okuphezulu namandla okuphuka kwensimu kagesi enamandla, kanye namagagasi agxilile. isimo.I-Silicon Carbide SiC e-Western Minmetals (SC) Corporation ingahlinzekwa ngosayizi we-2″ 3' 4“ kanye no-6″ (50mm, 75mm, 100mm, 150mm) ububanzi, enohlobo lwe-n, i-semi-insulating noma i-dummy wafer yezimboni. kanye nesicelo selabhorethri.Noma yikuphi ukucaciswa okwenziwe ngezifiso kungesixazululo esiphelele kumakhasimende ethu emhlabeni jikelele.

Izinhlelo zokusebenza

Iwafer yekhwalithi ephezulu ye-4H/6H Silicon Carbide SiC ilungele ukwenziwa kwezinto eziningi zikagesi ezisheshayo, ezishisa kakhulu nezinamandla kagesi njenge-Schottky diode & SBD, ama-MOSFET nama-JFET ashintsha amandla aphezulu, njll. futhi into efiselekayo ocwaningweni nasekuthuthukisweni kwama-insulated-gate bipolar transistors kanye nama-thyristors.Njengesisetshenziswa se-semiconducting sesizukulwane esisha esivelele, i-Silicon Carbide SiC wafer iphinda isebenze njengesisakazi sokushisa esisebenza kahle ezingxenyeni zama-LED ezinamandla amakhulu, noma njengendawo engaphansi ezinzile nedumile yokukhula kwesendlalelo se-GaN esivuna ukuhlolwa kwesayensi okuqondiswe esikhathini esizayo.

Imininingwane

Omaka

Ukucaciswa Kwezobuchwepheshe

I-Silicon Carbide SiCkwa-Western Minmetals (SC) Corporation ingahlinzekwa ngosayizi we-2″ 3' 4“ kanye no-6″ (50mm, 75mm, 100mm, 150mm) ububanzi, enohlobo lwe-n, i-semi-insulating noma i-dummy wafer ukuze kusetshenziswe izimboni kanye nelabhorethri .Noma yikuphi ukucaciswa okwenziwe ngezifiso kuyisixazululo esiphelele kumakhasimende ethu emhlabeni jikelele.

| Ifomula yomugqa | I-SiC |

| Isisindo samangqamuzana | 40.1 |

| Isakhiwo sekristalu | I-Wurtzite |

| Ukubukeka | Okuqinile |

| I-Melting Point | 3103±40K |

| Iphuzu elibilayo | N/A |

| Ukuminyana ku-300K | 3.21 g/cm3 |

| Igebe Lamandla | (3.00-3.23) eV |

| Ukumelana kwangaphakathi | >1E5 Ω-cm |

| Inombolo ye-CAS | 409-21-2 |

| Inombolo ye-EC | 206-991-8 |

| Cha. | Izinto | Ukucaciswa Okujwayelekile | |||

| 1 | Usayizi we-SiC | 2" | 3" | 4" | 6" |

| 2 | Ububanzi mm | 50.8 0.38 | 76.2 0.38 | 100 0.5 | 150 0.5 |

| 3 | Indlela Yokukhula | I-MOCVD | I-MOCVD | I-MOCVD | I-MOCVD |

| 4 | Uhlobo lwe-Conductivity | 4H-N, 6H-N, 4H-SI, 6H-SI | |||

| 5 | Ukungazweli Ω-cm | 0.015-0.028;0.02-0.1;>1E5 | |||

| 6 | Ukuqondisa | 0°±0.5°;4.0° ukuya ku-<1120> | |||

| 7 | Ubukhulu μm | 330±25 | 330±25 | (350-500)±25 | (350-500)±25 |

| 8 | Indawo Eyisisekelo Yefulethi | <1-100>±5° | <1-100>±5° | <1-100>±5° | <1-100>±5° |

| 9 | Ubude Befulethi obuyinhloko mm | 16±1.7 | 22.2±3.2 | 32.5±2 | 47.5±2.5 |

| 10 | Indawo Yefulethi Yesibili | I-silicon ibheke phezulu: 90°, ngokwewashi ukusuka efulethini eliyinhloko ±5.0° | |||

| 11 | I-Second Flat Ubude mm | 8±1.7 | 11.2±1.5 | 18±2 | 22±2.5 |

| 12 | I-TTV μm max | 15 | 15 | 15 | 15 |

| 13 | Khothama μm max | 40 | 40 | 40 | 40 |

| 14 | I-Warp μm max | 60 | 60 | 60 | 60 |

| 15 | Ukukhishwa komphetho mm ubukhulu | 1 | 2 | 3 | 3 |

| 16 | I-Micropipe Density cm-2 | <5, izimboni;<15, ilebhu;<50, inhlanhla | |||

| 17 | Ukuhlukaniswa cm-2 | <3000, izimboni;<20000, ilebhu;<500000, dummy | |||

| 18 | I-Surface Roughness nm max | 1(Iphucuziwe), 0.5 (CMP) | |||

| 19 | Imifantu | Lutho, lwebanga lezimboni | |||

| 20 | Amapuleti aneHexagonal | Lutho, lwebanga lezimboni | |||

| 21 | Ukuklwebheka | ≤3mm, ubude obuphelele bungaphansi kobubanzi be-substrate | |||

| 22 | Ama-Edge Chips | Lutho, lwebanga lezimboni | |||

| 23 | Ukupakisha | Isiqukathi esilucwecwana esisodwa esivalwe esikhwameni esiyinhlanganisela ye-aluminium. | |||

I-Silicon Carbide SiC 4H/6HI-wafer yekhwalithi ephezulu ilungele ukwenziwa kwezinto eziningi ezishesha kakhulu, ezisezingeni eliphezulu nezinamandla kagesi afana ne-Schottky diode & SBD, ama-MOSFETs nama-JFET ashintsha amandla aphezulu, njll. Futhi iyimpahla efiselekayo ucwaningo nokuthuthukiswa kwe-insulated-gate bipolar transistors kanye nama-thyristors.Njengesisetshenziswa se-semiconducting sesizukulwane esisha esivelele, i-Silicon Carbide SiC wafer iphinda isebenze njengesisakazi sokushisa esisebenza kahle ezingxenyeni zama-LED ezinamandla amakhulu, noma njengendawo engaphansi ezinzile nedumile yokukhula kwesendlalelo se-GaN esivuna ukuhlolwa kwesayensi okuqondiswe esikhathini esizayo.

Amathiphu Okuthenga

- Isampula Itholakala Lapho Ucelwa

- Ukuphepha Ukulethwa Kwempahla Nge-Courier/Air/Sea

- Ukuphathwa Kwekhwalithi ye-COA/COC

- Ukupakisha Okuvikelekile & Kalula

- Ukupakisha Okujwayelekile kwe-UN Kuyatholakala Lapho Ucelwa

- ISO9001:2015 Certified

- Imigomo ye-CPT/CIP/FOB/CFR Nge-Incoterms 2010

- Imigomo Yokukhokha Eguquguqukayo T/TD/PL/C Iyamukeleka

- Amasevisi Aphelele Asemuva Kokuthengisa

- Ukuhlolwa Kwekhwalithi Ngesikhungo Sesikhathi Esigcwele

- Ukuvunyelwa Kwemithethonqubo ye-Rohs/REACH

- Izivumelwano Ezingadaluli NDA

- Inqubomgomo Yezambiwayo Engangqubuzani

- Ukubuyekezwa Okujwayelekile Kokuphathwa Kwemvelo

- Ukufezekiswa Kwesibopho Somphakathi

I-Silicon Carbide SiC

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu